The Filling line consists devices brand of ( KRONES/STORK).

Discharger bottle is not operated at all.

All elements of a filling line are efficient and ready to work.

A filling line also includes all transporters to

boxes, cartons, bottles and piping to each devices.

Efficiency of the bottling line is 10.000-15,000 bottles/hour -

it does not matter whether it is 0,33L bottle or 1L bottle.

Thanks to filling line we can produce fizzy drinks, still drinks,

water, wine, cider (lightly fizzy)

The machine turns on aluminum, caps

Main label and other label on the bottle.

Equipment included:

1. Discharger - to unloading bottles. Type of bottles 4x23W

Efficiency to 1200 boxes per hour.(Year of the production 1993)

Dimonsisions of bottles: diameter 60 -92mm

Height 150-310mm

Dimonsisions of boxes: length 400-485mm, width 280-410mm

2. Cartoner - device is used to unpacking and stick togther

complex cartons (Year of the production 1995)

3. Packer of bottles - is used to pack fullfill bottles to boxes and cartons.

(Year of the production 1995)

4. Carton sealer - is used for carton sealing, which were packed bottles.

(Year of the production 1995)

5. Palletizer - is used for is used for stacking boxes or cartons with unfilled

bottles on pallets + transporters (Year of the production 1995)

6. Wrapper - is used for wraping

7. Mixer/ saturator - is used for preparing drinks and mixing with CO2

(Year of the production 1992)

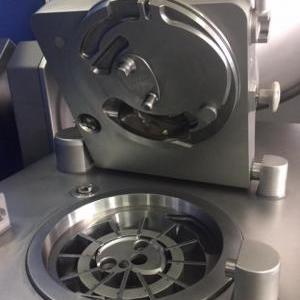

8. Monoblock, pouring machine, lebeler - all those devices are in one machine.

Is used for pouring, capping, labeling. Pouring machine is adopted to pouring botlles 0,25-1L

Pouring machine has 40fillers. (Year of the production 1993).

9. Ink printer. (Year of the production 2010).

10. Washer bottles

11.Steam generator - Efficiency 1000 kg / h The generator includes:

Water softening plant + fuel oil tank (Year of the production 1996).

12.Water treatment plant.

13. Boxes washer

14. Chip station -